|

| |

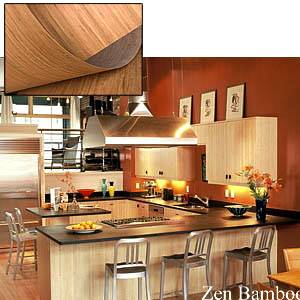

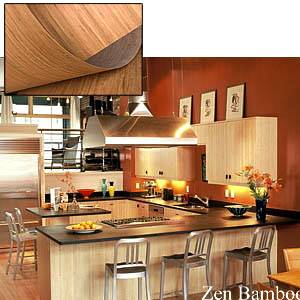

Uses:

Canyon Peak manufactures furniture grade bamboo veneer for

interior applications. Intended uses: cabinetry, furniture, interior paneling,

wall treatments and any other interior application where veneer wood products

are needed to be used.

Recommendations for Storage and Handling:

The following basic steps in handling and storage

are recommended to help avoid or minimize some of the problems associated with

wood movement.

-

Veneer should be stored flat.

-

Humidity and temperature controls that are

capable of maintaining a constant 40 to 60% relative humidity and 65 to 75°F

should be installed.

-

Extreme heat or coldness should be avoided.

-

Veneer stored in an uncontrolled environment

should be brought into the fabrication area 24 to 48 hours prior to being

processed. Evenly distributed weight of the stack will help the veneer

acclimate uniformly.

-

All exposed veneer surfaces should be sealed.

-

Allowance for linear expansion should be

incorporated into the design of the product.

-

Veneer should not be taken to a job site until

the site is completely ready for the product to be installed. It should be

allowed to acclimate to the job site before installation.

-

Veneer should not be installed over wet or

unfinished drywall.

-

The finished product should not be installed

until after it has been heated, ventilated, and cooled.

Finishes & Adhesives:

Independent testing was performed to ensure that the

adhesive between the bamboo slats is compatible with methyl alcohol and methyl

ethyl ketone-based products. The adhesive used in the back of our

1/42” paper-fleece backing meets specifications as a D-4 waterproof glue. Veneer

must be bonded to a suitable substrate of a reliable quality. MDF (medium

density fiberboard) is the most stable substrate, followed by industrial

particleboard, veneer-core plywood, and the least stable substrate is hardwood.

We do not recommend direct application to drywall, plaster walls, concrete walls

or cardboard products, as delaminating may occur. Veneer should be applied to

MDF substrate to cover these surfaces. Installation over substrates that have

been treated with a fire-retardant agent is not recommended. If using a hot

press method to laminate veneer, the best temperature is at 120° celsius. When

applying finishes, avoid over-saturation of the veneer surface. Follow

manufacturer’s suggested temperature and thickness for application. We recommend

testing the adhesive or finish you wish to use to ensure the overall

compatibility between the treatment, the veneer, and the installed environment.

Please note that the adhesive used to manufacture the veneer is not food grade.

If the surface is to be used for food preparation, a food grade sealer is

recommended.

Due to varying application environments and situations, these

guidelines do not guarantee results and should be used as a supplemental source

of information only. For more information about relative humidity and its

relationship to moisture content, please reference the Architectural Woodwork

Institute (AWI) web site at

www.awinet.org and the Hardwood Plywood and

Veneer Association (HPVA) website at www.hpva.org.

|

![]() Gardeners' Corner

Kids'

Garden

Sustainable Garden

Go

Shopping

Gardeners' Corner

Kids'

Garden

Sustainable Garden

Go

Shopping![]()